- info@sastherm.com

- 00393202628331

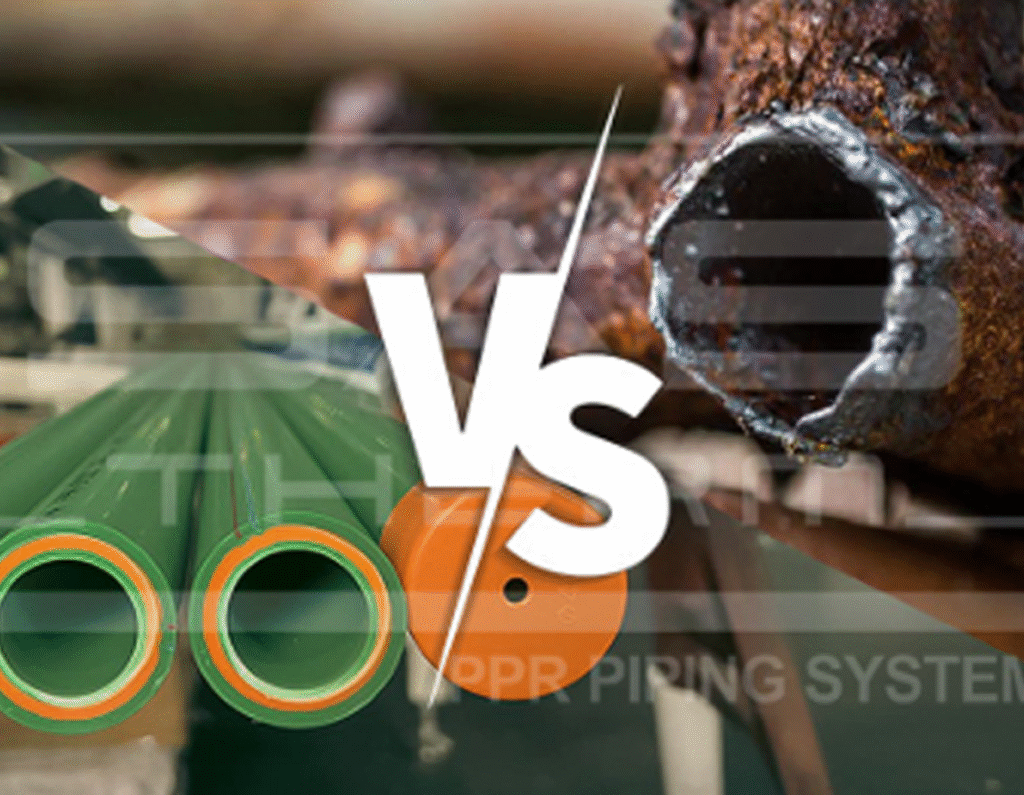

In the world of plumbing, the last few decades have seen a significant shift in materials and technologies.

While traditional systems such as galvanized steel fittings and older plastics (PVC) were once dominant,

modern PPR piping systems have emerged as a more efficient, durable, and reliable solution.

In this article, we explore the key differences between these systems, and why PPR has become the first

choice for engineers and contractors worldwide.

1. Materials and Manufacturing

• Traditional Systems:

Made of galvanized steel pipes and fittings, which are heavy, prone

to internal corrosion over time, and require threading tools or welding

for installation. These materials often degrade faster in harsh

environments, especially when exposed to humidity or acidic water.

• PPR Systems:

Made from Polypropylene Random Copolymer (Type 3), PPR pipes

are lightweight, corrosion-resistant, and long-lasting with a lifespan

exceeding 50 years. Heat fusion welding ensures leak-proof joints and

ease of installation, although it requires a specialized heat fusion tool

that is easy to operate and ensures consistent performance.

Note: Installation time can be reduced by up to 40% compared to galvanized

systems.

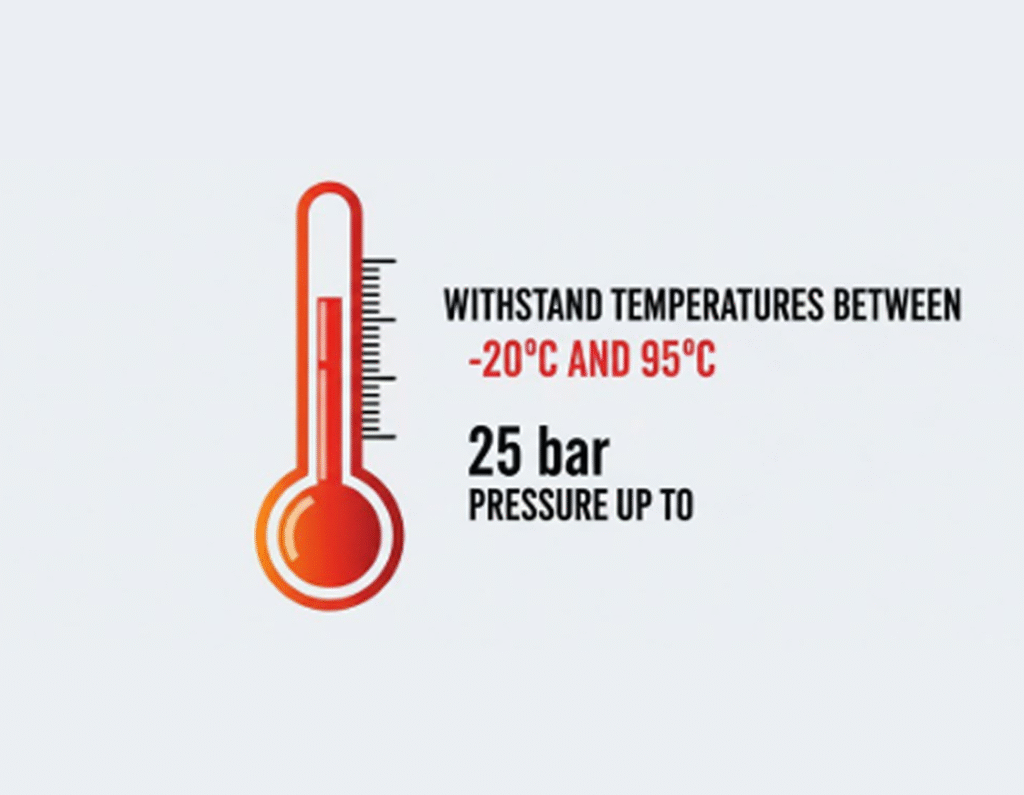

2. Pressure and Temperature Resistance

• Traditional Systems:

Typically have limited

resistance to high pressure

and heat. Galvanized steel

can corrode and weaken over

time under thermal stress.

• PPR Systems:

Can withstand temperatures

up to 95°C and pressure up

to 25 bar, making them ideal

for hot and cold water supply

and heating systems.

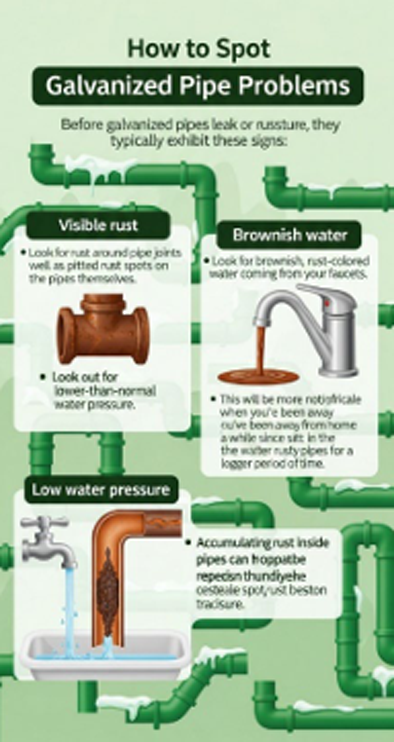

3. Water Safety and Hygiene

• Traditional Systems:

Internal corrosion or scaling may affect

water color, taste, or quality.

• PPR Systems:

Non-toxic, non-reactive, and approved for

drinking water applications (often certified

by bodies like WRAS or NSF). Maintains

water purity.

4. Ease of Installation and Maintenance

• Traditional Systems:

Require skilled labor, threading machines,

welding equipment, and take more time to

install.

PPR Systems:

Easy and fast to install using heat fusion tools.

Reduces labor costs and installation time

significantly.

5. Long-Term Cost Efficiency

• Traditional Systems:

Higher maintenance costs due to corrosion, leakage, or pipe degradation.

• PPR Systems:

Low maintenance, long service life (50+ years), and fewer repairs — making it a smart long-term

investment.

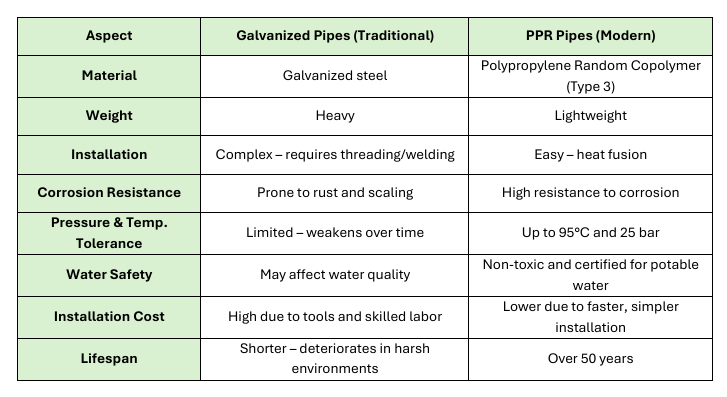

Comparison Table – PPR vs. Galvanized Pipes

Conclusion

Modern PPR piping systems offer a complete solution that combines safety, durability, flexibility, and

cost-effectiveness. They are not just an alternative to traditional plumbing — they have become the new

standard in residential, commercial, and industrial projects alike.

is a specialized company focused on the engineering design

and development of high-performance PPR (polypropylene random copolymer) pipe fittings and

accessories

09:00 Am - 6:00 Pm

© 2025 Created with sastherm.com